What You Should Know About CNC Machining

What You Should Know About CNC Machining

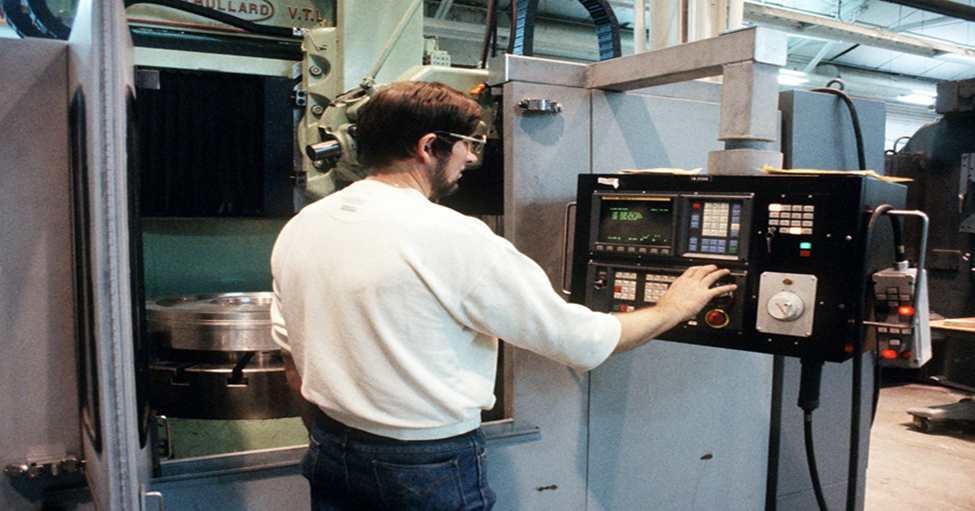

In the past few decades, the developed industry had to rely on active human labor, wide efforts, and pointlessly long production periods. Though, the manufacturing industry has improved significantly with today’s technology. And one of these revolutions is computer numerical control or CNC machining. Huge production businesses and manufacturers often capitalize on having their CNC machines. Nevertheless, more and more industry owners are now identifying the benefits of using CNC machining services.Â

What is CNC Machining?

It is an electronic or computerized manufacturing procedure in which pre-programmed software and code control the effort of production tools. CNC machining controls a variety of complex machinery, such as lathes, grinders, and turning mills, all of which are used to cut, shape, and manufacture various parts and prototypes. This procedure is appropriate for an extensive range of materials, including plastics, wood, metals, foam, glass, and compounds, and is applied in various industries, such as huge CNC machining, parts machining and prototyping for telecommunications, And CNC aerospace parts machining, which requires stricter tolerances than other productions. In more technical terms, machining is a form of mitigation, which means that the material is removed during the process. A CNC machine practices fast-moving cutters starting with a block material to quickly carve and cut away materials to create a finished part.

4 Primary Types of CNC Machines

1: CNC Mills

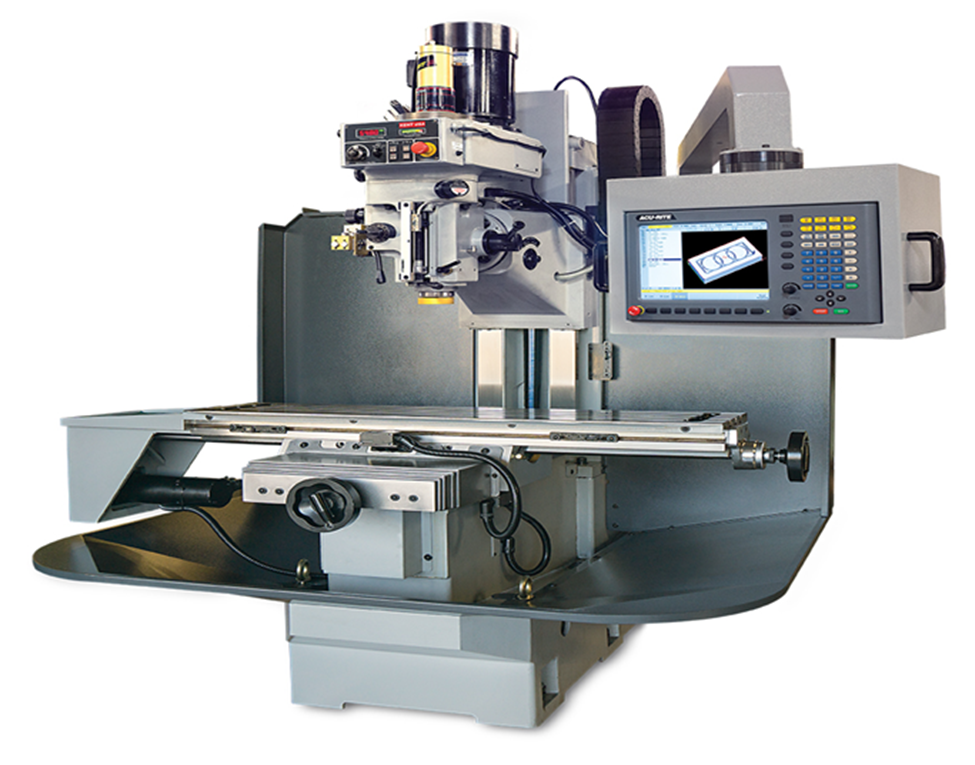

CNC mills are the most common type of CNC machine. It is known for its excellent accuracy and lenience. This CNC machine structures built-in tools for drilling and cutting and can be used for a variety of tasks, including tapping, boring, drilling, and cutting gears. CNC milling involves the machine bed, where the work-piece is securely placed. There is also a cutting instrument that rotates rapidly. The measure of this instrument and machine bed depends on the number of axes of movement your machine has, but for a mutual 3-axis machine, the bed moves back and forth and left to right, while the instrument moves up and down. If you are aiming to get swift cnc milling service, there are a number of options for you in this type.

2: CNC Laser Cutting

A CNC laser cutting machine is designed to cut hard materials using a highly focused laser. It offers a high level of accuracy and a better level of finishes than other CNC machines. In addition, this kind of CNC machine is well-known for manufacturing clean designs and is often used for decorative works such as marking or engraving machine modules.

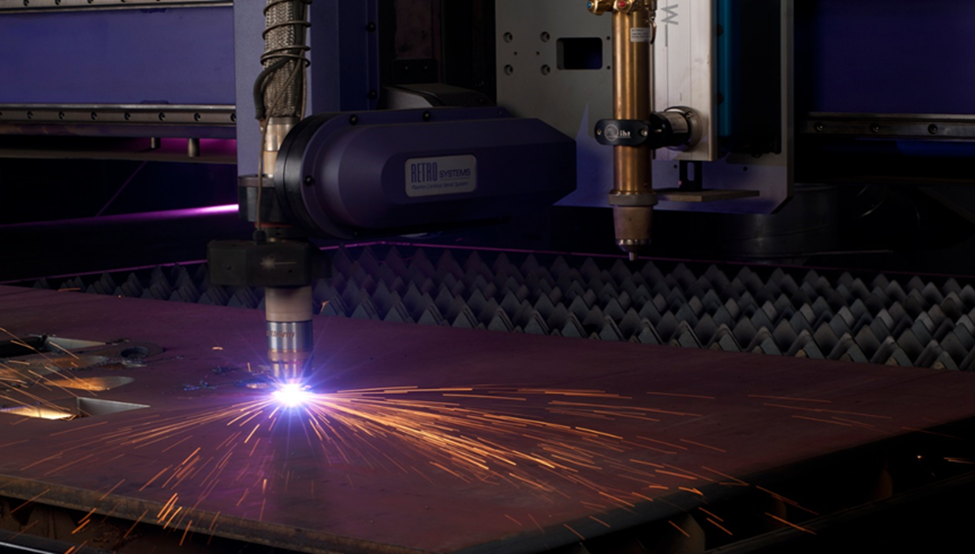

3: CNC Plasma Cutting

Like CNC laser cutting machines, CNC plasma cutting machines are also used for cutting hard materials. But instead of using lasers, this mechanism uses an energetic plasma flashlight that can reach up to 50,000 degrees Fahrenheit. CNC plasma cutters are commonly used in heavy industries such as aerospace, automobiles, and construction.

4: CNC Lathes

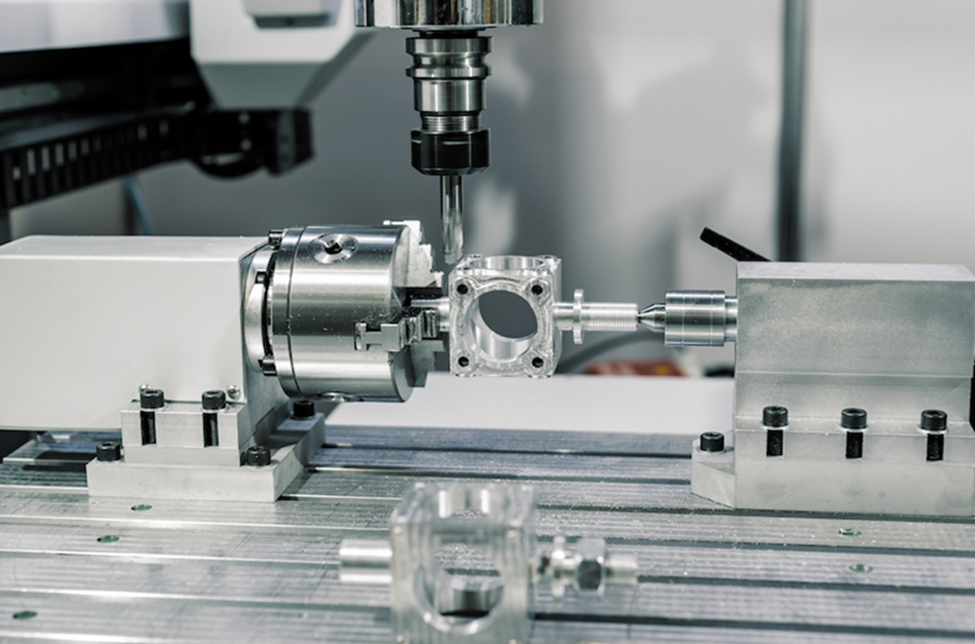

A CNC lathe machine is the opposite of CNC milling. Instead of moving the material to cut it, the material is rotated by itself because it is cut with a CNC lathe. In the middle is a lathe that holds the material in position and is best suited for flat, conical, or cylindrical-shaped products.

The CAD Model Designing Process

The CNC machining procedure begins with creating a 3D or 2D CAD design. Using computer-aided software (CAD) software, manufacturers and designers can develop a model or present their products or components with the necessary technical features, such as geometries and dimensions to form. When the CAD project is completed, the designer transfers it to a CNC-compatible file format such as IGES or STEP.

CNC Machines Programming Languages

CNC machines depend heavily on programming. Generally, CNC machining programming codes are separated into two codes.

G-Code

G code or geometric code refers to the verbal used to move a machine. It limits the speed and motion of the cutting heads of the machine.

M-Code

M-code is also known as miscellaneous code or machine code; M-code provides all the information that G-code ignores. This includes instructions on program stops, tool changes, or the use of coolant.

Programmers need to enter the correct codes to ensure that the CNC machines are working properly. Without these codes, CNC machining would be useless. Once these codes are written and loaded into the CNC machine, the code will work mostly.

Industries That Use CNC Machining

CNC machining is valuable for any trader or industry that requires the production of identical parts or components. Sectors working in CNC machining include automotive, electrical, mining, defense, industrial machinery, agriculture, textiles, food, and beverages. In particular, CNC machining is considered significant for engineers in businesses where high accuracy is required, including in the robotics, medical and healthcare sectors, and aerospace production. The use of technologies such as waterjet cutting has escalated in the past few years. There are no boundaries to who can use CNC machining. If your production needs a part made with accuracy or in huge amounts, either for construction or prototyping, CNC is the true resolution for you.  Â

Comments are closed