Waterjet Cutting: An Essential Role in Construction

Waterjet Cutting: An Essential Role in Construction

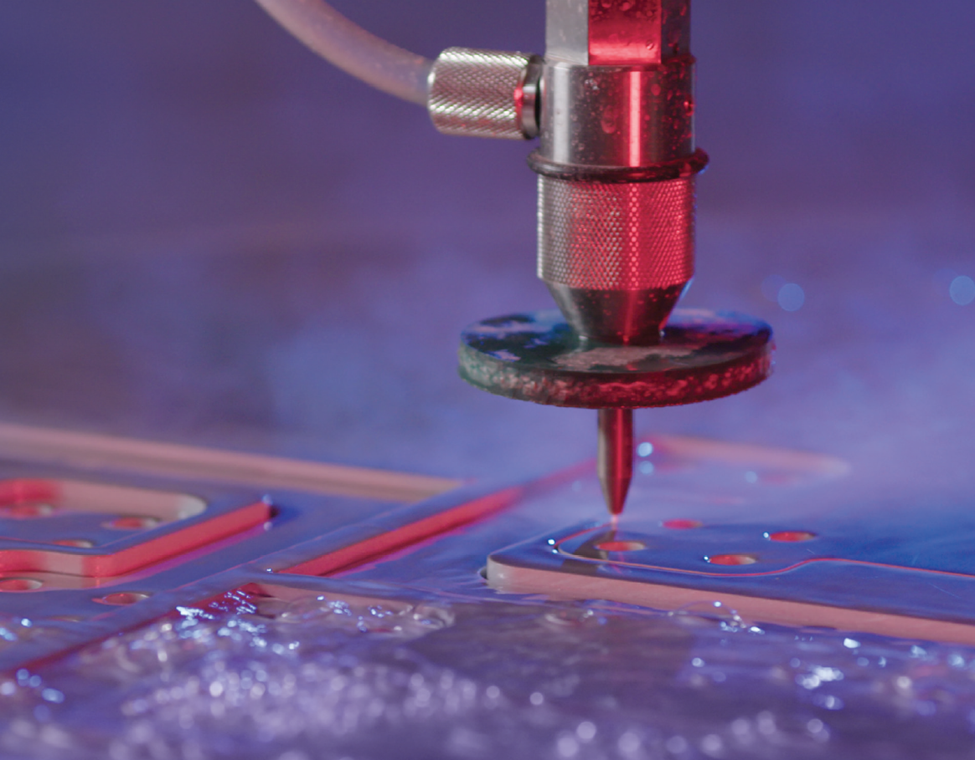

Water jet cutting is a process that uses high pressure water jets that are able to cut through various types of materials. The jets are dispensed through a small precision nozzle. There are two different approaches that water jet cutting uses to cut through different materials.

The first is known as pure cutting. This approach uses a very small nozzle to employ a concentrated jet stream of water. It is mostly used on soft materials such as plastic or rubber.

The second one is abrasive cutting. This one is mostly implemented in construction. The jets consist of tiny abrasive particles and they are concentrated through a small jeweled nozzle. Abrasive water jet cutting is used on harder materials such as glass or metal. A good example of such machines is the water jet cutting machine by Techni Waterjet.

Why Abrasive Waterjet Technology is Essential in the Construction Industry

The construction industry is broad and covers different fields such as bridges, houses and commercial buildings. Therefore, abrasive waterjet technology has multiple advantages in this very industry. This form of waterjet cutting is economical, very precise and it is relatively inexpensive.

Abrasive waterjet cutting is employed to cut through metals as well. It is able to cut through aluminum, steel beams, railway bridges and titanium. The versatility and the effectiveness of this technology is what makes it useful to the construction industry.

Common Uses for Waterjet Cutting in Construction

Stone

Stone is one of the main materials used in construction. The waterjet cutting technology in this case is used to cut through some of its components; customized stepping stones, border tiles, vanity tops, wall and floor inlays as well as kitchen tops.

Metals

This is the most common use of Abrasive waterjet cutting technology in the construction industry. The machine is used to cut through some of the following metals; aluminum, brass, steel, nickel as well as titanium.

Glass

In construction, waterjets are used to cut through splashbacks in the kitchen and bathroom, stained glass in lamp shades or those in mosaics, shower screens(particularly those but not limited to that are frameless),laminated glass, table tops, bullet-proof glass and inlays of floor among others.

Soft material

These include; rubber, cork, plastic and dense foams.

Benefits of WaterJet Cutting in the Construction Industry

There are various benefits to the waterjet cutting technology generally and in the construction industry as well. We will expound on some of those benefits:

1. Waterjet Cutting is very precise

The precision of this technology is really outstanding. It is able to cut through most of the construction material at great speed yet the cuts and edges are clean.

2. Environmental Friendly

These days, the manufacturing industry and generally every other industry has gone green. All the other cutting methods have proven to be futile in maintaining the cleanliness of the environment except waterjet cutting. This technology is able to cut through construction material without producing too much waste and pollutants.

The waterjet cutting technology does not in any way, produce toxic gasses or poisonous substances. Its mechanism uses only pure water in conjunction with natural abrasives. Any of the left-over particles or matter does not in any way affect the environment.

3. Versatility

There is a wide range of possibilities when dealing with waterjet cutting technology. You can use it to cut through hard materials in a limitless number of ways.

The jets cut through the construction materials in a way that does not distort the mechanical properties of that material and without weakening it. In addition to that, the waterjet cutting machines come in sizable units that can be implemented on the different workpieces available.

4.   Smooth finishes

Waterjet cutting machines are capable of cutting through construction material without creating imperfections, rough edges and surfaces. This eliminates the process of having to perform secondary finishing since the end product usually has minimal bumps and the edges are smooth.

5. Easy to use

The water pump and cutting tool that is used in the waterjet cutting machine produces high velocity water jets. All the components integrated in the machine are not difficult to use once you have been taught how to use them. It is not a complex machine to use.

6. Cost effectiveness

Cost saving is one of the issues that the manufacturing industry has to keep in mind when implementing any of the cutting methods. One of the most significant benefits of the waterjet cutting technology is that it is cost effective.

The main cost that is associated with this technology is that of running the machine. The cost is far much less than that of any cutting processes there are.

7. Product size control

Waterjet cutting technology cannot even be compared to cutting with a saw of a blade, by hand. The machine is capable of cutting through workpieces in only those dimensions and sizes that are required. Making the construction products and materials easier to work with.

In conclusion

Waterjet cutting technology is far much better than traditional cutting methods especially when implemented in the construction industry. It is therefore one of the best methods you can ever adopt and employ to enhance productivity and efficiency.

Comments are closed