Using Drum Cutters for Surface Preparation and Wall Demolition

Using Drum Cutters for Surface Preparation and Wall Demolition

The post Using Drum Cutters for Surface Preparation and Wall Demolition appeared first on UK Construction Blog.

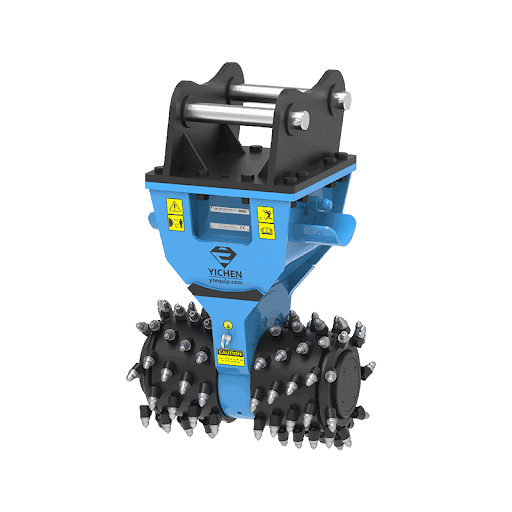

The landscape of modern construction is ever-evolving, demanding tools that match its dynamic nature. Enter drum cutters, the powerful excavator attachments that are redefining efficiency and precision in construction equipment. Whether it’s in the realm of surface preparation, wall demolition, or concrete removal, these robust machines provide a sophisticated solution to some of the most challenging aspects of construction work.

Fusing the brute force required for demolition with the delicate touch needed for preparation tasks, drum cutters are essential for construction professionals seeking to streamline their projects. With their unique ability to scale walls and shave off surfaces with minimal debris and disruption, drum cutters offer an unparalleled blend of power and finesse.

Key Takeaways

- Drum cutters are versatile tools for precise and efficient surface preparation and wall demolition.

- As excavator attachments, they bring added functionality to existing construction equipment.

- Their adeptness at concrete removal makes them a valuable asset in both renovation and new construction.

- Adopting drum cutters can elevate the overall productivity of construction projects.

- By reducing manual labor, drum cutters contribute to a faster completion timeline.

The Advantages of Utilizing Drum Cutters in Construction

As the construction industry evolves, the quest for more efficient and precise tools takes precedence. The introduction of the drum cutter attachment has marked a significant step forward in meeting the demands for versatile rock excavation and trenching equipment. Unlike traditional cutting tools, drum cutters offer a combination of rapid progress and accuracy, proving to be invaluable on the modern construction site.

Increased Efficiency and Precision

Equipped with robust cutting teeth, drum cutters can navigate through hard materials with ease, making them highly effective for road milling and demanding rock excavation tasks. The precise nature of these attachments minimizes material overcut and waste, thereby saving time and resources. An excavation project that would typically take hours with manual tools can now be completed much faster, showcasing the drum cutter’s exceptional efficiency.

Reduced Vibration and Noise Levels

In the heart of urban areas, low noise demolition is not just preferred but often required by regulations. Drum cutters stand out as a safe excavator attachment due to their comparatively lower noise and vibration levels. As an excavator rock grinder, it operates with minimal disturbance, making it a considerate option for populated or sensitive environments. This benefit is especially important when working near hospitals, schools, or residential areas where high noise levels could cause significant disruptions.

Improved Safety on Construction Sites

Safety is paramount on any construction site, and drum cutters contribute positively to this aspect. Their design allows for controlled demolition, which, along with their low vibration features, results in a safe excavator attachment choice for workers. By reducing the risk of flying debris and lessening operator fatigue from vibrations, drum cutters help foster construction safety. This careful balance of power and control not only enhances efficiency but also protects the health and safety of construction teams.

Indubitably, the integration of drum cutters into construction protocols aligns with industry progression towards safer, quieter, and more precise construction methods. The transformation they bring to excavation and demolition tasks is a testament to the significant role of innovation in fostering construction safety and operational excellence.

Understanding Drum Cutter Applications and Limitations

Drum cutters are becoming increasingly popular in the construction industry due to their versatile applications, which extend to surface preparation and intricate concrete removal tasks. These heavy-duty attachments for excavators are particularly valued for their precise cutting abilities and ability to reduce concrete into manageable fragments. A classic example of drum cutter uses is during road reconstruction, where they grind up the asphalt for easy recycling, illustrating their pivotal role in both deconstruction and recycling processes.

Yet, for all their strengths, limitations of excavation attachments such as drum cutters must be acknowledged to maximize their potential and ensure that they are used in the most appropriate contexts. A major limitation results from their weight and size; being quite substantial, they necessitate a corresponding excavator of matching capacity to manage the load, dictating the scale of projects they can be applied to.

“Understanding both the capabilities and limitations of drum cutters is essential for construction teams to leverage their efficiency without overextending the equipment’s intended use.�

Regarding performance, while drum cutters are celebrated for their concrete removal efficiency, they can struggle with materials that are extremely hard or require more aggressive demolition techniques. In such cases, alternative methods like hydraulic breakers might be necessary. Additionally, the upkeep of drum cutters is non-negligible; the teeth on the drums wear down over time and need to be replaced to maintain effectiveness, which contributes to the overall cost of operation.

- Drum Cutter Advantages:

- Precision cutting

- Minimal vibration and noise

- Reduction of material to facilitate recycling

- Drum Cutter Limitations:

- Requires large, capable carrier equipment

- Limited application in extremely hard materials

- Maintenance and operational costs

In conclusion, while the versatility of drum cutters in construction is evident, it is critical for professionals to consider the physical and operational limitations of these excavation attachments. Doing so ensures the judicious use of technology and maintains project efficiency and cost-effectiveness. As such, drum cutters are a powerful asset in the construction industry, provided their use aligns with project needs and equipment capabilities.

Conclusion

In reflecting on the uses of drum cutters in the construction landscape, we identify a harmonious blend of force and precision that revolutionizes traditional methods. The advantages of drum cutter technology are manifold and significantly contribute to the advancement of construction efficiency. These excavator attachments are more than mere tools; they’re catalysts of change, propelling the industry towards more sophisticated, safe, and savvy machinery. This article has underlined the excavator drum cutter benefits encompassing their precise nature, low-vibration profile, and ability to enhance safety on job sites, highlighting them as a paragon of modern construction equipment.

Comments are closed