Unlocking the Efficiency: How Soft Strip Demolition Streamlines Renovation Projects

Unlocking the Efficiency: How Soft Strip Demolition Streamlines Renovation Projects

The post Unlocking the Efficiency: How Soft Strip Demolition Streamlines Renovation Projects appeared first on UK Construction Blog.

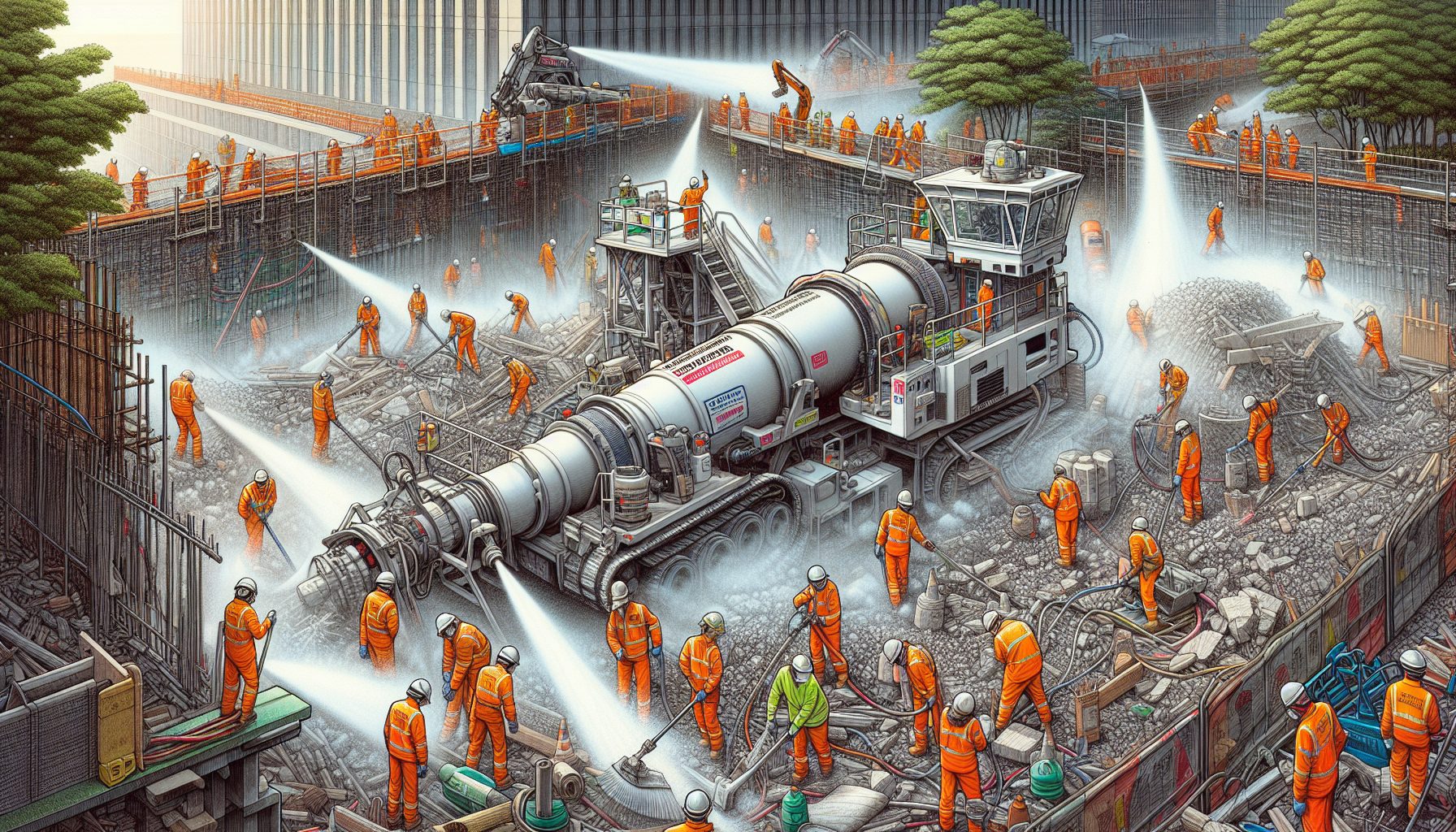

Planning a renovation or demolition project? Soft strip demolition is a crucial early step, clearing out all non-structural components and paving the way for a safe and efficient worksite. This guide will help you understand how this process adds value to your project by saving costs, adhering to environmental standards, and simplifying the renovation journey. Discover the strategies, benefits, and best practices of soft strip demolition to ensure the success of your project.

Key Takeaways

- Soft strip demolition is a careful process of removing non-structural elements from buildings, prepping for renovation or demolition while preserving structural integrity and allowing potential reuse of materials.

- The process is strategic and advantageous, offering cost efficiencies, environmental benefits through waste management and recycling, and ensures safe disposal of hazardous materials like asbestos and lead-based paints.

- Choosing the right soft strip demolition contractor involves assessing their experience, equipment, adherence to safety measures, and the comprehensiveness of their liability insurance, as well as comparing detailed quotes to ensure transparency and value.

Understanding Soft Strip Demolition

Soft strip demolition is not about wreaking havoc on a building; instead, it’s a meticulous exercise in removing non-structural elements from a site before the demolition or renovation of the structure takes place. Imagine it as a surgical process, delicately extracting non-structural features both inside and outside a building, including:

- internal walls

- floor coverings

- fixtures

- mechanical and electrical systems, including dismantling cable trays, wires, and lines

It’s not just about the visible fixtures; soft strip demolition also involves the removal of hidden elements.

Whether it’s preparing a building for a complete makeover or setting the stage for complete demolition, the soft strip process is instrumental. It’s an initial, critical phase that clears the way, ensuring a smooth and efficient renovation or demolition project. The soft strip demolition services are like the unsung heroes, performing behind-the-scenes tasks that play a pivotal role in the success of any renovation or demolition project.

The Soft Strip Process

The soft strip process is not a haphazard act of deconstruction; it begins with thorough planning, underpinned by internal and external visual surveys and meticulous risk assessments. These steps help preempt potential issues, ensuring that the ensuing demolition or renovation project proceeds smoothly and safely.

Safety is a cornerstone of any soft strip demolition project. Established safety measures, based on detailed risk assessments conducted well in advance, are deployed to ensure increased safety. This rigorous planning and risk mitigation are what sets the soft strip demolition process apart, ensuring a safe and efficient project execution.

Key Components Removed

The soft strip process involves the removal of various non-structural elements and fittings within a building. These may include:

- Internal walls

- Ceilings

- Staircases

- Floor coverings

Floor coverings, although occasionally overlooked, are also stripped out during this process.

The soft stripping does not stop at visible fixtures. It extends deeper into the building’s infrastructure. Mechanical and electrical fittings are systematically disconnected and removed, preparing the building for renovation or complete demolition.

This safe removal of components ensures that the building is stripped down to its bare essentials, ready for its next phase of life.

Advantages of Soft Strip Demolition

The soft strip demolition process is not just a demolition procedure; it’s a strategic approach that offers several benefits. One of the most compelling advantages is cost efficiency. By minimizing damage to remaining structures, money is saved on repairs, and removed items can potentially be refitted at a later date. This contributes to the overall cost efficiency of renovation projects, making soft strip demolition a financially savvy choice.

The advantages of the soft strip process include:

- Monetary benefits

- Environmental friendliness

- Recycling of building materials

- Conforming to recognized environmental management standards like ISO14001

- Reducing potential damage to the remaining structure

- Enhancing the preservation of the building during renovation

Hazardous Materials Management

During a soft strip demolition process, special attention is given to the management of hazardous materials. For example, asbestos-containing materials (ACMs) and lead-based paints, which pose significant health risks, must be securely disposed of. Asbestos removal is typically carried out in parallel with the soft strip operation by asbestos specialists offering compliant removal and remediation services.

Similarly, specialized teams manage and remove lead-based paint, often found in older properties, ensuring safety and compliance. Comprehensive reports are provided by these teams to identify and manage the presence of lead prior to demolition. This meticulous handling of hazardous materials underscores the importance of environmental cleaning and decontamination in the soft strip demolition process.

Waste Management and Recycling

Waste management and recycling are integral components of the soft strip demolition process. By enabling the salvage and recycling of materials, the process reduces waste and minimizes environmental impact, contributing to construction sustainability. The priority placed on recycling building materials exemplifies responsible environmental practices.

Professional soft strip demolition teams adhere to recognized environmental standards during the process, as confirmed by accreditations like the ISO14001 UKAS accreditation of the Reddish Vale team. These teams can also provide thorough documentation regarding the recycling of materials, ensuring transparency and accountability. Therefore, the soft strip demolition process doesn’t just dismantle; it also rebuilds for the future through recycling and sustainable practices.

Challenges and Solutions in Soft Strip Demolition

Like any complex process, soft strip demolition comes with its own set of challenges. Some of the main challenges include:

- Maintaining project schedules and adhering to budgets

- Stringent local and federal regulations

- Securing the appropriate permits to avoid project delays and potential penalties

However, these challenges can be mitigated with proper planning, detailed strategies, and open communication with clients.

Worker and public safety is another crucial challenge that must be prioritized. This can be achieved through comprehensive training, utilization of specialized equipment, and the implementation of strict safety protocols on-site. Moreover, managing environmental impacts and ensuring the preservation of structural integrity are key challenges that need to be addressed in the soft strip demolition process, reinforcing the importance of careful planning and proper risk assessments.

Noise and Dust Control

Noise and dust are inevitable by-products of any demolition process. However, soft strip demolition activities are planned to minimize noise disruption, with noisy work scheduled during daytime hours to mitigate impact on surrounding areas. This careful scheduling ensures that the process is as unobtrusive as possible.

Dust control is another crucial aspect of soft strip demolition. Measures such as water suppression, on-tool extraction systems, and the containment of dust creation zones with appropriate screening are employed. Workers are also equipped with respiratory protective equipment, supplemented by regular checks and maintenance of the dust suppression systems to ensure their effectiveness. These measures help protect workers from lung diseases that can result from inhaling dust, especially containing silica or wood, during soft strip demolition.

Site Accessibility and Regulations

The soft strip demolition costs can be significantly affected by the location of a building. This means that the expenses involved can vary based on where the building is situated. The overall cost of the soft strip demolition project can be impacted by factors such as accessibility, parking restrictions, and local regulations. These considerations should be carefully evaluated and planned for during the project’s cost estimation. Therefore, understanding these factors and planning accordingly is crucial for a cost-effective and efficient project.

Local regulations specific to the building’s location can further influence the cost and approach to soft strip demolition. Therefore, a thorough understanding of these regulations and how they apply to a specific project is necessary. This knowledge allows for better planning, smoother operations, and the successful execution of the soft strip demolition project.

Hiring a Soft Strip Demolition Contractor

Securing the right contractor is pivotal to the success of your soft strip demolition project. Experience is a critical factor to consider, as it indicates their capability to handle unique project challenges efficiently, thereby directly affecting the cost. A contractor’s reputation in the industry and past client feedback can provide insight into their level of expertise and reliability.

Ensuring a contractor has the necessary equipment and can offer services specific to the project, such as high-rise demolitions, is vital for effective soft strip demolition. When comparing costs, it’s advisable to obtain multiple quotes to evaluate the best value for money.

Here are some tips to consider when hiring a contractor for soft strip demolition:

- Make sure the contractor has the necessary equipment and expertise for the specific project requirements.

- Obtain multiple quotes to compare costs and evaluate the best value for money.

- Agree on a clear payment structure and be cautious about upfront payments for jobs that do not require materials.

Lastly, select a demolition company that has comprehensive liability insurance and adheres to high health and safety standards to protect both property and individuals.

Questions to Ask Potential Contractors

Choosing the right contractor for your soft strip demolition project is not a decision to be taken lightly. It’s crucial to ask potential contractors about their experience, equipment, and services specific to your project. A contractor’s past performance and approach to safety should also be scrutinized, and they should be able to provide references from previous clients.

Comparing quotes from various contractors is essential to assess differences in costs, services provided, and the level of expertise in soft strip demolition. This comparison enables you to make an informed decision, ensuring you engage a contractor who can deliver the results you desire within the agreed timeline and budget.

Comparing Quotes and Services

When comparing quotes for soft strip demolition, prioritize transparency and authenticity of contractors who adhere to their initial quote to prevent unexpected costs and ensure service quality of existing services.

Here are some tips to help you make an informed decision:

- Seek detailed quotes from various contractors for soft strip demolition projects.

- Prioritize contractors who provide transparent and detailed breakdowns of costs.

- Ensure that all aspects of the project are covered in the quotes.

By following these tips, you can choose a contractor who offers the best value for your soft strip demolition project.

The average cost for soft strip demolition in the UK ranges from £10 to £25 per square meter, giving a benchmark for cost comparison when evaluating quotes. Ensure a comprehensive comparison by considering the contractor’s reputation for sticking to quotes, the detail and clarity of the quotes received, and the overall cost in relation to market averages. This thorough comparison ensures you get the best value for your money and a contractor who can deliver as promised.

Real-Life Applications of Soft Strip Demolition

The versatility of soft strip demolition is truly impressive. It’s a method used across various types of projects, including:

- Commercial spaces

- Industrial buildings

- Large retail spaces undergoing extensive strip out for comprehensive renovation

- Warehouses being refurbished

Soft strip demolition plays a pivotal role in all of these projects.

These real-life applications demonstrate that soft strip demolition is an effective solution for preparing buildings for renovation, regardless of their initial use. The method’s adaptability and efficiency make it a go-to strategy for any renovation or demolition project.

Preserving Historical Buildings

Historical buildings often require special care and attention during renovation. Soft strip demolition is employed in the refurbishment of these structures to maintain their original character while allowing for the incorporation of modern amenities.

The Crosshall’s building, known for housing the UK’s first juvenile court, is a prime example of this. It underwent a soft strip demolition that preserved the facade while allowing for internal renovations and modifications for new uses. This balance between preserving the architectural integrity and charm of historical buildings and updating them to fit contemporary needs is a testament to the versatility and value of soft strip demolition.

Commercial and Residential Projects

Soft strip demolition is not limited to historical buildings; it’s also extensively used in commercial and residential projects. From office blocks in Birmingham and Solihull to an expansive office building in Ashford, soft strip demolition has proven its worth in the commercial sphere.

Beyond commercial contexts, soft strip demolition has been employed in educational settings, with schools like Chipping Norton School and another in Milton Keynes undergoing internal soft stripping for classroom and space refurbishments. These examples highlight the adaptability of soft strip demolition, demonstrating its effectiveness across a range of project types.

Summary

Throughout this blog, we’ve explored the intricacies of soft strip demolition, highlighting its process, benefits, challenges, and real-life applications. It’s clear that this method is an essential part of renovation and demolition projects, offering cost efficiency, environmental sustainability, and preservation of structural integrity. Whether you’re refurbishing a historical building or planning a commercial project, soft strip demolition provides a strategic and efficient approach that can make a significant difference. So, the next time you embark on a renovation project, remember, the secret to unlocking efficiency could well lie in the power of soft strip demolition!

Frequently Asked Questions

What is soft strip demolition?

Soft strip demolition is the removal of non-structural elements from a building prior to renovation or demolition, encompassing internal walls, floor coverings, and mechanical/electrical systems.

Why is soft strip demolition beneficial?

Soft strip demolition is beneficial because it is cost-efficient, environmentally friendly, and preserves the remaining structure, while also helping manage hazardous materials and waste for safety and sustainability.

What challenges can arise during soft strip demolition?

Challenges in soft strip demolition include maintaining project schedules, navigating regulations, ensuring safety, managing environmental impacts, and preserving structural integrity, but these can be mitigated through careful planning and communication.

How do I choose a reliable soft strip demolition contractor?

To choose a reliable soft strip demolition contractor, consider their experience, reputation, safety standards, equipment, and project-specific services, and compare quotes to get the best value.

Where is soft strip demolition used?

Soft strip demolition is used in a wide range of projects, including commercial spaces, industrial buildings, historical building refurbishments, office buildings, retail spaces, and educational settings. It is a versatile method used in different types of construction and renovation projects.

Comments are closed