Exploring the Different Types of Shuttering in Construction and Their Uses

Exploring the Different Types of Shuttering in Construction and Their Uses

Ever wondered how concrete structures maintain their shape and strength during construction? The answer lies in the world of shuttering in construction, a crucial yet often overlooked aspect. As we dive into the various types of shuttering materials and techniques, prepare to be amazed by the innovative systems that enable complex and unique structures to come to life.

Short Summary

- Shuttering is a critical component of concrete construction, with various materials and techniques providing structural support during the hardening process.

- Best practices for shuttering in construction include proper surveying, planning, formwork removal, quality control and inspections.

- Innovative shuttering systems offer unique solutions to complex structures by combining traditional methods with modern technologies.

The Importance of Shuttering in Construction

Shuttering is at the heart of concrete construction, providing temporary support to wet concrete until it sets and hardens into the desired shape. From foundation shuttering to formwork shuttering, this process is essential for creating sturdy concrete structures that stand the test of time.

The choice of shuttering materials and techniques directly impacts the overall quality and cost-effectiveness of construction projects. With various types of shuttering available, each tailored to specific needs, it’s crucial to understand their unique characteristics and applications in the construction industry.

Role of Shuttering in Concrete Construction

In concrete construction, shuttering serves as the formwork for beams, columns, walls, and slabs, ensuring that fluid concrete stays in place while it hardens. One might think of shuttering as the skeleton that holds wet concrete together, preventing it from collapsing, leaking, or losing its shape.

Without proper shuttering, even the best-designed concrete structures could fail, resulting in costly repairs or even catastrophic accidents.

Factors Affecting Shuttering Choice

Choosing the right shuttering system for a construction project is a critical decision, influenced by several factors such as cost, availability, strength, durability, and aesthetics. Labor costs, material expenses, and ease of installation all come into play when selecting a suitable shuttering material.

Additionally, the specific requirements of the concrete structure and the desired finish must be taken into consideration to ensure a successful project.

Common Materials Used in Shuttering

Shuttering materials come in various forms, each with its own advantages and drawbacks. Common materials include timber, steel, plywood, and plastic, with some innovative systems even incorporating fabric or insulation material. The choice of material depends on the specific requirements of the project, such as the desired shape, smoothness, and strength of the resulting concrete surface.

In this section, we’ll explore the characteristics of these materials and their applications in the construction industry.

Timber Shuttering

Timber shuttering is a popular choice in construction due to its cost-effectiveness and ease of use. However, it has a limited lifespan and may not be the most efficient option for large-scale projects. Conventional timber formwork, typically used for smaller works, can be reused up to 10 to 12 times.

While timber offers the advantage of a smooth and even surface, it may require additional finishing treatments to achieve the desired result.

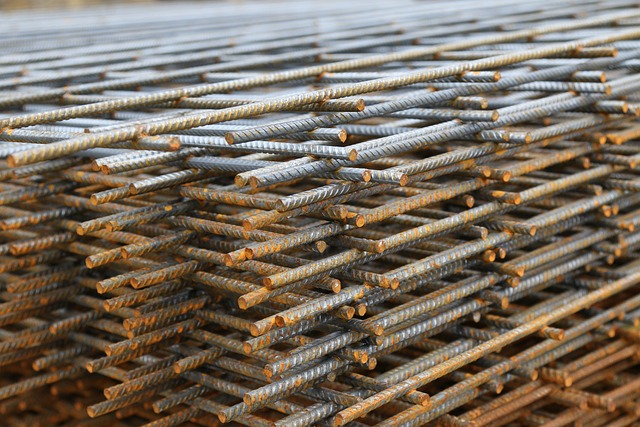

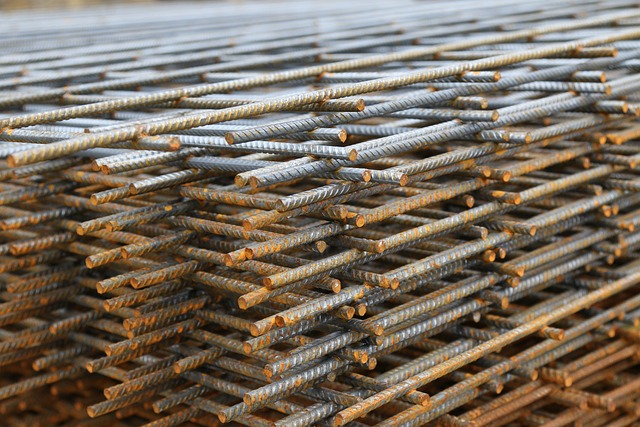

Steel Shuttering

Steel shuttering is gaining popularity due to its long life span, multiple reuses, and suitability for curved or circular structures. Composed of thin steel plates secured with small steel angles, steel shuttering can accommodate large volumes of concrete and provides a highly polished, even finish to the concrete surface.

The primary downside of steel formwork is its weight, making it difficult to move into place and potentially requiring heavy construction machinery for proper panel placement.

Plywood Formwork

Plywood shuttering is a cost-effective alternative to timber shuttering due to its strength, durability, and lightweight properties. Engineered wooden sheets are used in formwork for concrete elements, providing a smooth surface that doesn’t require additional finishing treatments.

The cost of plywood shuttering is generally comparable to that of timber shuttering and may be more cost-effective in certain cases.

Plastic Shuttering

Plastic shuttering is a lightweight, repetitive task-focused formwork made of robust plastic, suitable for low-cost housing estates and large sections. It is advantageous for projects with similar shapes and designs, as it requires less concrete than other shuttering systems, leading to cost savings.

However, plastic shuttering lacks the flexibility of timber and may not be suitable for all construction projects.

Shuttering Techniques for Various Structural Components

Shuttering techniques are designed to cater to the specific requirements of various structural components, such as foundation, column, wall, and slab shuttering. Each technique utilizes specific materials and thicknesses, ensuring that the resulting concrete structures meet the desired strength and quality standards.

In this section, we will explore the different shuttering techniques and how they are applied to various structural components.

Foundation Shuttering

Foundation shuttering designs vary based on the type of foundation, with differences in formwork for strip and private foundations determined by size, primarily height.

This type of shuttering ensures that concrete maintains a uniform shape and strength during the foundation stage of construction, minimizing the risk of defects and enabling intricate shapes and designs.

Column Shuttering

Column shuttering is constructed according to the column’s shape and dimensions, with panels anchored in the soil using bolts. This technique allows for the creation of sturdy columns that can withstand the lateral loads present in reinforced concrete columns.

Proper shuttering and reinforcement are essential for ensuring the column’s strength and durability, as well as preventing concrete from leaking out during vibration and curing.

Wall Shuttering

Wall shuttering is used for constructing RCC or shear walls in dams and basements, made of upright timbers, plywood, and bracing boards. It is essential to ensure that the wall shuttering is efficiently propped and rigidly constructed, as the lateral loads applied to it are significantly less than those applied to column shuttering.

By providing a firm base and temporary support, wall shuttering allows for the creation of strong, durable concrete walls that can withstand various loads and stresses.

Slab Shuttering

Beam shuttering is a type of formwork used in RCC framed buildings, with prefabricated parts based on the beam size and table fabrication done on-site. This technique enables the construction of horizontal members, such as slabs, providing temporary support for fresh concrete as it sets and hardens into the desired shape.

By ensuring a consistent and smooth surface, slab shuttering plays a crucial role in the overall quality and stability of the resulting concrete structure.

Innovative Shuttering Systems

In recent years, innovative shuttering systems have emerged, providing unique solutions for complex and challenging structures. These systems often combine the advantages of traditional shuttering materials and techniques with cutting-edge technologies and materials, resulting in increased efficiency, cost savings, and enhanced design possibilities.

In this section, we will explore some of the most innovative shuttering systems currently available, such as tunnel formwork, fabric shuttering, and permanent insulated shuttering.

Tunnel Formwork

Tunnel formwork is an innovative system that allows casting walls and slabs in a single operation, resulting in a cellular reinforced structure with high-quality surfaces for various applications. This technique combines the speed, quality, and precision of factory/off-site manufacturing with the flexibility and economics of in-situ construction, making it particularly advantageous for projects requiring repeating cellular construction, such as residential towers and hotels.

The advantages of tunnel formwork include reduced labor costs, improved safety, and faster construction times. Additionally, the system is highly adaptable and can be used for a variety of applications, including walls, columns, and slabs. The system also allows for the use of the system.

Fabric Shuttering

Fabric formworks are a new and flexible shuttering technique that uses high-strength and lightweight fabric sheets to produce unique shapes and designs. These formworks require less concrete than traditional systems, resulting in cost savings and a reduced environmental impact.

Fabric shuttering can be used in both precast and cast-in-place applications, offering versatility and creative freedom in construction projects.

Permanent Insulated Shuttering

Permanent insulated formwork is a lightweight insulation material used as formwork to support walls during casting, left in place to ensure thermal insulation and a consistent surface for finishing. This innovative shuttering system not only provides long-term insulation, but also offers potential thermal, fire-resistant, acoustic, and rodent-resistant characteristics.

With its combination of structural support and insulation, permanent insulated shuttering is a practical and efficient solution for various construction projects.

Best Practices for Shuttering in Construction

To ensure the best results in shuttering projects, it is essential to follow best practices at every stage of the process. From proper surveying and planning to timely formwork removal, these practices guarantee the quality and safety of the resulting concrete structures.

In this section, we will delve into the key best practices for shuttering in construction, including quality control and inspection.

Proper Surveying and Planning

Proper surveying and planning are crucial in construction, as they ensure accurate measurements and analysis of the site, establishing the location and alignment of various structures. In the context of shuttering, this planning process involves evaluating the type of shuttering material, size and shape of the formwork, and the concrete to be used.

By carefully considering these factors, construction teams can avoid potential problems and obstacles, leading to a smoother and more efficient construction process.

Timely Formwork Removal

Timely formwork removal is essential to prevent damage to the concrete and ensure the safety of personnel on the construction site. Concrete must reach a minimum strength of twice the strain it is exposed to at the time of formwork removal before it can be safely removed.

By adhering to these guidelines, construction teams can minimize the risk of defects and accidents, ensuring a successful project outcome.

Quality Control and Inspection

Quality control and inspection are critical aspects of shuttering in construction, as they ensure proper shuttering installation and concrete curing. Regular inspections and tests help guarantee compliance with minimum standards of material and workmanship, preventing defects and ensuring the facility performs as designed.

By following these best practices, construction teams can avoid costly mistakes and ensure the highest possible quality for their concrete structures.

Summary

In conclusion, shuttering plays a vital role in the construction of concrete structures, providing temporary support and ensuring the desired shape and quality of the resulting structures. With various materials and techniques available, it is crucial to understand their unique characteristics and applications to choose the best solution for each project. By following best practices and embracing innovative shuttering systems, construction teams can achieve exceptional results, creating durable and aesthetically pleasing concrete structures that stand the test of time. As the construction industry continues to evolve, so too will the world of shuttering, offering new and exciting possibilities for the future.

Frequently Asked Questions

What is shuttering in construction?

Shuttering in construction is the process of providing support and stability to concrete during the casting process. It is typically created using wood or steel, allowing the poured concrete to keep its shape until it is hardened.

Shuttering is an important part of the construction process, as it ensures that the concrete is properly supported and will not collapse or crack during the curing process. It also helps to create.

What is shuttering and types of shuttering?

Shuttering is a form of moulding used to shape concrete into a desired form until it has hardened. There are different types of shuttering such as timber, aluminium, steel and plastic formworks.

The most appropriate shuttering method will be chosen depending on the requirements of the project.

What is the function of shuttering?

Shuttering is a crucial step in the process of building concrete structures, providing the needed support to the structure until it gains enough stability on its own. It usually consists of a combination of wooden and steel elements, forming the correct shape for the structure until it can stand on its own.

Therefore, shuttering is essential for creating strong, stable concrete structures.

What is the importance of shuttering in construction?

Shuttering plays an essential role in construction projects as it is the temporary formwork or mould that is used to provide support and stability to the concrete until it hardens. It helps to give the structure the desired shape and strength, ensuring a finished structure of great quality.

Exploring the Different Types of Shuttering in Construction and Their Uses

Ever wondered how concrete structures maintain their shape and strength during construction? The answer lies in the world of shuttering in construction, a crucial yet often overlooked aspect. As we dive into the various types of shuttering materials and techniques, prepare to be amazed by the innovative systems that enable complex and unique structures to come to life.

Short Summary

- Shuttering is a critical component of concrete construction, with various materials and techniques providing structural support during the hardening process.

- Best practices for shuttering in construction include proper surveying, planning, formwork removal, quality control and inspections.

- Innovative shuttering systems offer unique solutions to complex structures by combining traditional methods with modern technologies.

The Importance of Shuttering in Construction

Shuttering is at the heart of concrete construction, providing temporary support to wet concrete until it sets and hardens into the desired shape. From foundation shuttering to formwork shuttering, this process is essential for creating sturdy concrete structures that stand the test of time.

The choice of shuttering materials and techniques directly impacts the overall quality and cost-effectiveness of construction projects. With various types of shuttering available, each tailored to specific needs, it’s crucial to understand their unique characteristics and applications in the construction industry.

Role of Shuttering in Concrete Construction

In concrete construction, shuttering serves as the formwork for beams, columns, walls, and slabs, ensuring that fluid concrete stays in place while it hardens. One might think of shuttering as the skeleton that holds wet concrete together, preventing it from collapsing, leaking, or losing its shape.

Without proper shuttering, even the best-designed concrete structures could fail, resulting in costly repairs or even catastrophic accidents.

Factors Affecting Shuttering Choice

Choosing the right shuttering system for a construction project is a critical decision, influenced by several factors such as cost, availability, strength, durability, and aesthetics. Labor costs, material expenses, and ease of installation all come into play when selecting a suitable shuttering material.

Additionally, the specific requirements of the concrete structure and the desired finish must be taken into consideration to ensure a successful project.

Common Materials Used in Shuttering

Shuttering materials come in various forms, each with its own advantages and drawbacks. Common materials include timber, steel, plywood, and plastic, with some innovative systems even incorporating fabric or insulation material. The choice of material depends on the specific requirements of the project, such as the desired shape, smoothness, and strength of the resulting concrete surface.

In this section, we’ll explore the characteristics of these materials and their applications in the construction industry.

Timber Shuttering

Timber shuttering is a popular choice in construction due to its cost-effectiveness and ease of use. However, it has a limited lifespan and may not be the most efficient option for large-scale projects. Conventional timber formwork, typically used for smaller works, can be reused up to 10 to 12 times.

While timber offers the advantage of a smooth and even surface, it may require additional finishing treatments to achieve the desired result.

Steel Shuttering

Steel shuttering is gaining popularity due to its long life span, multiple reuses, and suitability for curved or circular structures. Composed of thin steel plates secured with small steel angles, steel shuttering can accommodate large volumes of concrete and provides a highly polished, even finish to the concrete surface.

The primary downside of steel formwork is its weight, making it difficult to move into place and potentially requiring heavy construction machinery for proper panel placement.

Plywood Formwork

Plywood shuttering is a cost-effective alternative to timber shuttering due to its strength, durability, and lightweight properties. Engineered wooden sheets are used in formwork for concrete elements, providing a smooth surface that doesn’t require additional finishing treatments.

The cost of plywood shuttering is generally comparable to that of timber shuttering and may be more cost-effective in certain cases.

Plastic Shuttering

Plastic shuttering is a lightweight, repetitive task-focused formwork made of robust plastic, suitable for low-cost housing estates and large sections. It is advantageous for projects with similar shapes and designs, as it requires less concrete than other shuttering systems, leading to cost savings.

However, plastic shuttering lacks the flexibility of timber and may not be suitable for all construction projects.

Shuttering Techniques for Various Structural Components

Shuttering techniques are designed to cater to the specific requirements of various structural components, such as foundation, column, wall, and slab shuttering. Each technique utilizes specific materials and thicknesses, ensuring that the resulting concrete structures meet the desired strength and quality standards.

In this section, we will explore the different shuttering techniques and how they are applied to various structural components.

Foundation Shuttering

Foundation shuttering designs vary based on the type of foundation, with differences in formwork for strip and private foundations determined by size, primarily height.

This type of shuttering ensures that concrete maintains a uniform shape and strength during the foundation stage of construction, minimizing the risk of defects and enabling intricate shapes and designs.

Column Shuttering

Column shuttering is constructed according to the column’s shape and dimensions, with panels anchored in the soil using bolts. This technique allows for the creation of sturdy columns that can withstand the lateral loads present in reinforced concrete columns.

Proper shuttering and reinforcement are essential for ensuring the column’s strength and durability, as well as preventing concrete from leaking out during vibration and curing.

Wall Shuttering

Wall shuttering is used for constructing RCC or shear walls in dams and basements, made of upright timbers, plywood, and bracing boards. It is essential to ensure that the wall shuttering is efficiently propped and rigidly constructed, as the lateral loads applied to it are significantly less than those applied to column shuttering.

By providing a firm base and temporary support, wall shuttering allows for the creation of strong, durable concrete walls that can withstand various loads and stresses.

Slab Shuttering

Beam shuttering is a type of formwork used in RCC framed buildings, with prefabricated parts based on the beam size and table fabrication done on-site. This technique enables the construction of horizontal members, such as slabs, providing temporary support for fresh concrete as it sets and hardens into the desired shape.

By ensuring a consistent and smooth surface, slab shuttering plays a crucial role in the overall quality and stability of the resulting concrete structure.

Innovative Shuttering Systems

In recent years, innovative shuttering systems have emerged, providing unique solutions for complex and challenging structures. These systems often combine the advantages of traditional shuttering materials and techniques with cutting-edge technologies and materials, resulting in increased efficiency, cost savings, and enhanced design possibilities.

In this section, we will explore some of the most innovative shuttering systems currently available, such as tunnel formwork, fabric shuttering, and permanent insulated shuttering.

Tunnel Formwork

Tunnel formwork is an innovative system that allows casting walls and slabs in a single operation, resulting in a cellular reinforced structure with high-quality surfaces for various applications. This technique combines the speed, quality, and precision of factory/off-site manufacturing with the flexibility and economics of in-situ construction, making it particularly advantageous for projects requiring repeating cellular construction, such as residential towers and hotels.

The advantages of tunnel formwork include reduced labor costs, improved safety, and faster construction times. Additionally, the system is highly adaptable and can be used for a variety of applications, including walls, columns, and slabs. The system also allows for the use of the system.

Fabric Shuttering

Fabric formworks are a new and flexible shuttering technique that uses high-strength and lightweight fabric sheets to produce unique shapes and designs. These formworks require less concrete than traditional systems, resulting in cost savings and a reduced environmental impact.

Fabric shuttering can be used in both precast and cast-in-place applications, offering versatility and creative freedom in construction projects.

Permanent Insulated Shuttering

Permanent insulated formwork is a lightweight insulation material used as formwork to support walls during casting, left in place to ensure thermal insulation and a consistent surface for finishing. This innovative shuttering system not only provides long-term insulation, but also offers potential thermal, fire-resistant, acoustic, and rodent-resistant characteristics.

With its combination of structural support and insulation, permanent insulated shuttering is a practical and efficient solution for various construction projects.

Best Practices for Shuttering in Construction

To ensure the best results in shuttering projects, it is essential to follow best practices at every stage of the process. From proper surveying and planning to timely formwork removal, these practices guarantee the quality and safety of the resulting concrete structures.

In this section, we will delve into the key best practices for shuttering in construction, including quality control and inspection.

Proper Surveying and Planning

Proper surveying and planning are crucial in construction, as they ensure accurate measurements and analysis of the site, establishing the location and alignment of various structures. In the context of shuttering, this planning process involves evaluating the type of shuttering material, size and shape of the formwork, and the concrete to be used.

By carefully considering these factors, construction teams can avoid potential problems and obstacles, leading to a smoother and more efficient construction process.

Timely Formwork Removal

Timely formwork removal is essential to prevent damage to the concrete and ensure the safety of personnel on the construction site. Concrete must reach a minimum strength of twice the strain it is exposed to at the time of formwork removal before it can be safely removed.

By adhering to these guidelines, construction teams can minimize the risk of defects and accidents, ensuring a successful project outcome.

Quality Control and Inspection

Quality control and inspection are critical aspects of shuttering in construction, as they ensure proper shuttering installation and concrete curing. Regular inspections and tests help guarantee compliance with minimum standards of material and workmanship, preventing defects and ensuring the facility performs as designed.

By following these best practices, construction teams can avoid costly mistakes and ensure the highest possible quality for their concrete structures.

Summary

In conclusion, shuttering plays a vital role in the construction of concrete structures, providing temporary support and ensuring the desired shape and quality of the resulting structures. With various materials and techniques available, it is crucial to understand their unique characteristics and applications to choose the best solution for each project. By following best practices and embracing innovative shuttering systems, construction teams can achieve exceptional results, creating durable and aesthetically pleasing concrete structures that stand the test of time. As the construction industry continues to evolve, so too will the world of shuttering, offering new and exciting possibilities for the future.

Frequently Asked Questions

What is shuttering in construction?

Shuttering in construction is the process of providing support and stability to concrete during the casting process. It is typically created using wood or steel, allowing the poured concrete to keep its shape until it is hardened.

Shuttering is an important part of the construction process, as it ensures that the concrete is properly supported and will not collapse or crack during the curing process. It also helps to create.

What is shuttering and types of shuttering?

Shuttering is a form of moulding used to shape concrete into a desired form until it has hardened. There are different types of shuttering such as timber, aluminium, steel and plastic formworks.

The most appropriate shuttering method will be chosen depending on the requirements of the project.

What is the function of shuttering?

Shuttering is a crucial step in the process of building concrete structures, providing the needed support to the structure until it gains enough stability on its own. It usually consists of a combination of wooden and steel elements, forming the correct shape for the structure until it can stand on its own.

Therefore, shuttering is essential for creating strong, stable concrete structures.

What is the importance of shuttering in construction?

Shuttering plays an essential role in construction projects as it is the temporary formwork or mould that is used to provide support and stability to the concrete until it hardens. It helps to give the structure the desired shape and strength, ensuring a finished structure of great quality.

Comments are closed