Electrostatic and Other Types of Ultrasonic Sensors & Sensor Kits

How much do you know about ultrasonic sensors? They are beneficial in the performance of all kinds of detection tasks as part of their industrial applications.

These devices can detect high-gloss and transparent objects in liquid, solid, powder, and granular form. They are tolerant of dust, dirt, smoke, and mist. Piezoelectric and electrostatic ultrasonic sensors are the two main categories.

Nevertheless, one should understand the working concept of proximity, retro-reflective, and through-beam probes. The principle of work and applications are specific to each model.

Learn more about each type in detail.

Electrostatic ultrasonic sensors

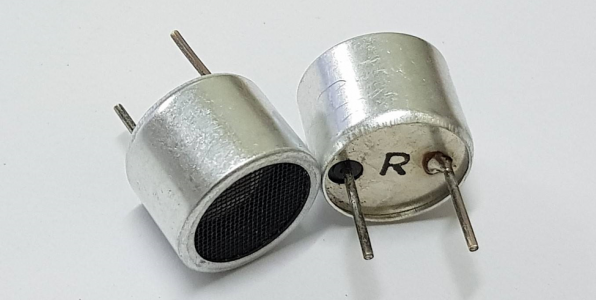

Ultrasonic sensors refer to devices that rely on energy transformation to measure the exact distance from the sensor to the target. They are classified into two types in accordance with their working phenomenon, referring to piezoelectric and electrostatic devices. The former uses piezoelectric materials for the generation of ultrasonic waves. This type offers higher pressure levels but a narrow bandwidth.

Electrostatic sensors, on the other hand, have a wider bandwidth, which provides signals of short duration to be generated and received. They are composed of a conductive membrane resting on a conductive backplate.

When an electrical signal is applied between the backplate and membrane, the latter moves either toward or away from the former. When an ultrasound signal is applied, the membrane undergoes vibrations. There is a variety of Electrostatic Ultrasonic Sensors and sensor kits online. They are equipped with numerous features to fit any application.

Ultrasonic proximity sensors

These proximity devices use a sonic transducer that enables the transmission and reception of sound waves. It emits sonic waves that get reflected by objects and are once again received by the transducer. Following the emission, the sensor switches to receive mode. Sensing only takes place in the detection area, while adjustments can be made to the sensing range by using the device’s potentiometer.

In addition, sonic waves are optimally reflected from hard surfaces. Targets can be granules, powders, liquids, and solids. They are defined as square flat objects of multiple sizes, including 15 x 15 millimeters for scanning distances up to 250 mm, 30 x 30 millimeters for scanning distances up to 1000 mm, and 100 x 100 mm for scanning distances lower than 1000 mm.

Moreover, the intensity of the reflected signal is determined by the object’s size. The sensing distance gets reduced by detecting sound-absorbent materials. The maximum distance could be achieved if the maximum object’s roughness doesn’t exceed 0, 2 mm. Some typical sound-absorbing materials include cotton, wool, felt, cloth, foam rubber, etc.

Ultrasonic retro-reflective sensors

Retro-reflective sensors operate in a similar way to proximity models. The distance from these devices to the reflector is calculated by doing propagation time measurements. A reflector can be any stationary object that reflects sound. If the propagation time of the signal is identical to the distance from the reflector to the sensor, the device is considered to be in a non-active state. It changes to an active state when an object appears in the sensing distance.

The target should be a square object with a length of thirty millimeters. The reflector should be made of any material with solid sound reflection properties and of the same size as the standard target. For object detection at close range, the sound cone has to be completely covered in order for the echo not to return from the reflector.

In order to ensure reliable object detection in the rest of the operating range, the signal is supposed to be strong enough. Typical applications of these devices are inclined and irregularly shaped objects, sound-deflecting target objects, sound-absorbing materials, and others.

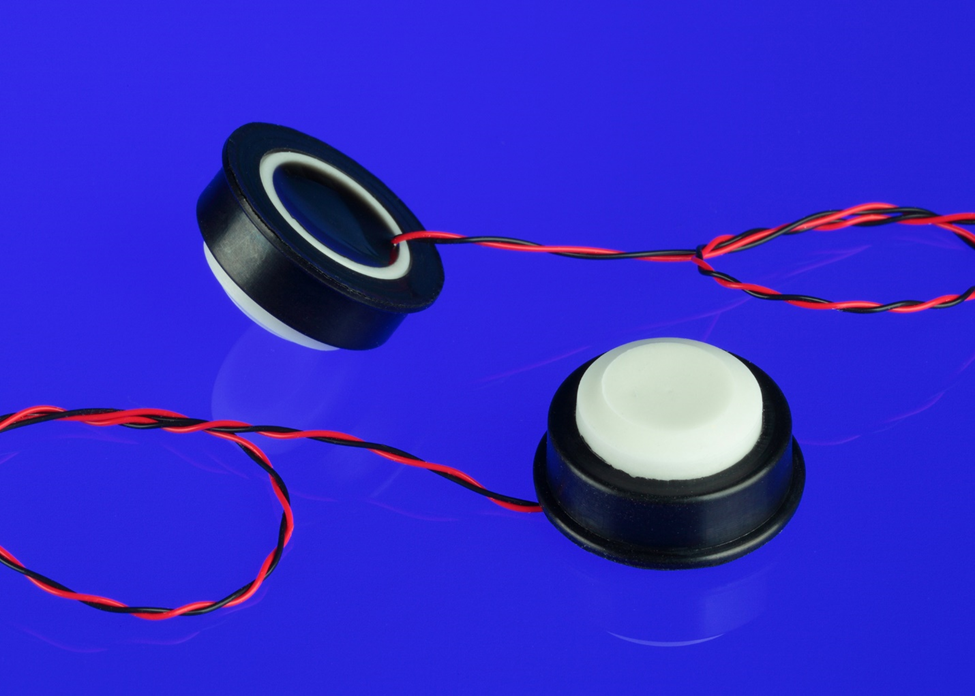

Through-beam sensors

Through-beam ultrasonic devices have separate housings for the emitter and the receiver. The emitter emits a continuous signal, which is recognized by the receiver. Whenever an object interrupts the sonic beam, the receiver reacts in a way by releasing an output signal. The presence of a built-in potentiometer allows users to adjust the input signal to their preferences. A LED light is used for indicating signal intensity.

Moreover, hysteresis is a term that users come across when purchasing such probes. It explains the difference between the operating and release point, marked as S1 and S2. When an object causes interruption to the sonic beam, the level of the signal has to be increased by approximately 75% for the output signal to be reset. The following link, https://www.britannica.com/science/hysteresis, provides a detailed explanation of the term hysteresis.

Through-beam ultrasonic models are known for their large ranges and short response times. Their typical applications include object detection in fast succession, counting objects from materials that are hard to detect, monitoring film breaks, monitoring transparent materials, etc.

Additional info on ultrasonic sensors

Many individuals are interested in learning how these devices respond to noise and interference. Acoustic noises whose frequency matches the receptiveness of the device are likely to interfere with its output. These noises are high-pitched, like a whistle, valve hissing, compressed air sounds, etc. When it comes to the influence of environmental conditions, temperature fluctuation has an effect on the speed of the sound waves produced by the device.

When the temperature increases, the sound waves travel faster to the target and back. Air currents are also believed to interfere with the path of the waves, making the sensor incapable of recognizing the correct target location. Also, these devices are supposed to warm up before the operation. All components should be stable in temperature for the accuracy in measurement not to be affected.

Another comparison people often make is between ultrasonic and optical sensors. The former is advantageous in wet environments and while sensing liquid levels, clear objects, and metallic surfaces. The latter, however, isn’t susceptible to wind and temperature fluctuations, providing a fast response.

To sum up

When looking for such products, you should consider their designs, operation principles, and features.

The product selection is extensive, but you can easily narrow it down if you have your preferences set!

Comments are closed